1. Overview of Lubricating Grease in Industrial Applications

Across all industrial machinery systems, from production lines and heavy mechanical equipment to precision transmission components, lubrication plays a fundamental role in ensuring stable operation, minimizing wear, and extending equipment service life.

While lubricating oil is commonly used in closed-loop circulation systems, lubricating grease is an irreplaceable solution for components operating under heavy loads, high rotational speeds such as bearings, harsh environments, or locations where frequent relubrication is impractical.

A clear understanding of what lubricating grease is, how it is structured, and how it behaves from a physical and chemical perspective enables businesses to select the right product, optimize maintenance costs, and significantly reduce the risk of unplanned downtime.

2. What Is Lubricating Grease? Chemical and Physical Fundamentals

Lubricating grease is a semi-solid lubricant composed of a base oil retained within a thickener system and enhanced with functional additives.

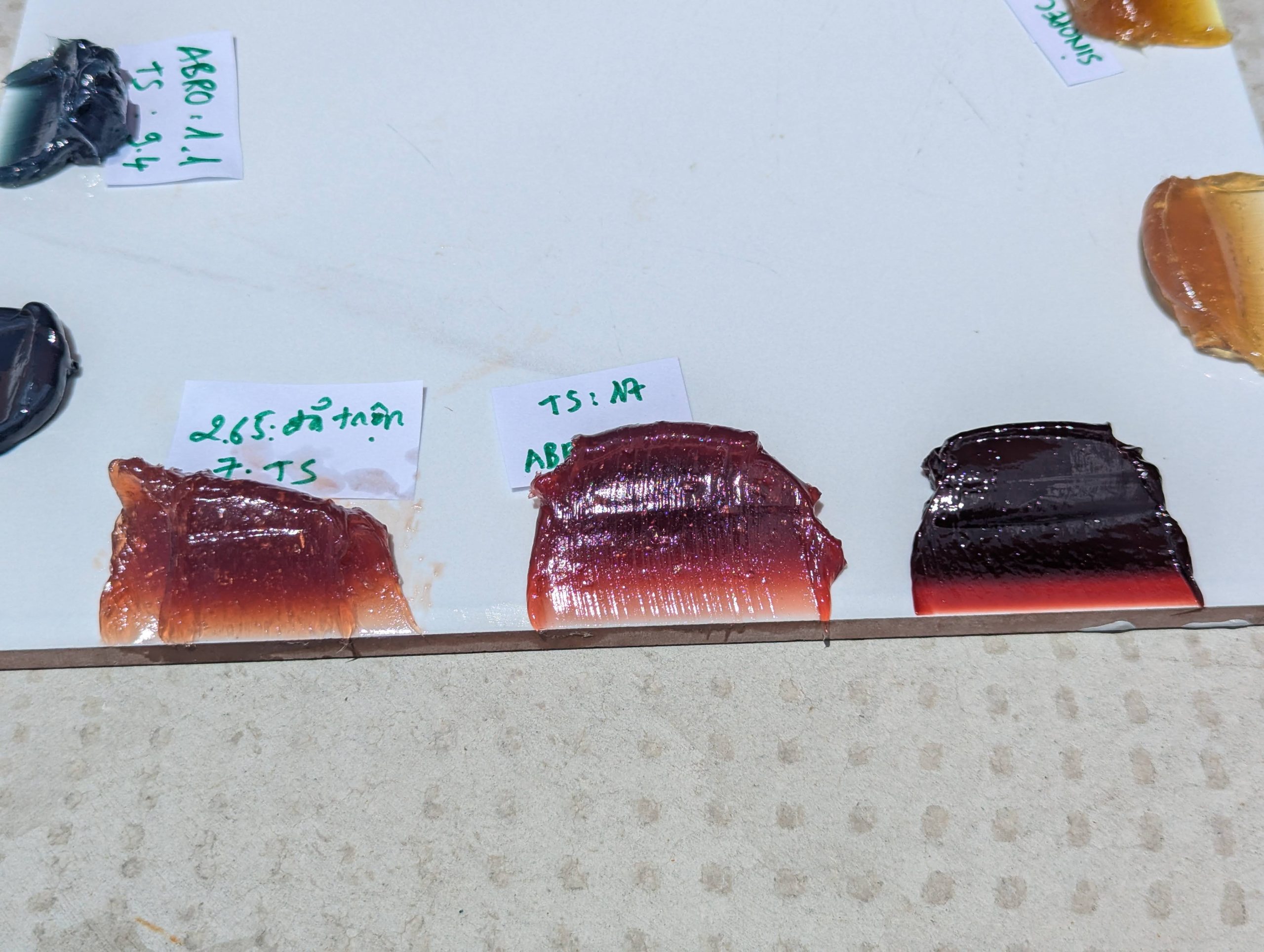

Image: Lubricating Grease from OEMGREASE.COM

From a chemical and physical standpoint, grease is not a homogeneous material. It is a colloidal system, where the base oil acts as the liquid phase, and the thickener forms a structural network that holds the oil in place at the lubrication point.

Thanks to this structure, lubricating grease offers several key advantages:

- Strong adhesion to metal surfaces

- Resistance to leakage or runoff compared to oil

- Reliable performance in sealed or open systems, under vibration, contamination, or intermittent motion

This unique behavior makes grease particularly suitable for demanding industrial environments.

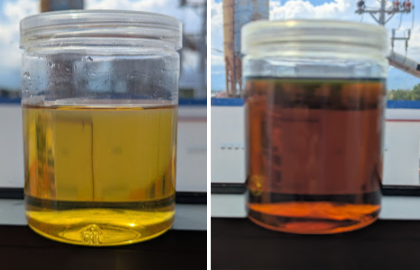

3. Differences Between Lubricating Grease and Lubricating Oil

Although both lubricating grease and oil are designed to reduce friction and wear, their characteristics and applications differ significantly.

Lubricating oil is fluid and free-flowing, making it ideal for continuous circulation systems, high-speed applications, and situations where heat dissipation is critical. In contrast, lubricating grease has a defined consistency that allows it to remain in place and provide long-term lubrication at specific contact points.

In industrial practice:

- Lubricating oil is commonly used for engines, enclosed gearboxes, and hydraulic systems

- Lubricating grease is preferred for bearings, open gears, couplings, guide rails, and hard-to-access components

Selecting the wrong lubricant oil instead of grease or vice versa, can result in ineffective lubrication, excessive heat generation, accelerated wear, and reduced equipment lifespan.

4. Structure of Lubricating Grease

4.1 Base Oil

Base oil typically represents 70–90% of the grease formulation and is the primary contributor to lubricating performance.

Common base oil types include:

- Mineral oil

- Synthetic oil

- Semi-synthetic oil

The choice of base oil directly influences temperature resistance, oxidation stability, and grease service life under real operating conditions.

4.2 Thickener System

The thickener determines grease consistency, oil retention capability, and mechanical stability. It forms a fibrous or network structure that prevents the oil from flowing away from the lubrication zone.

Common industrial thickener systems include:

- Lithium and Lithium Complex

- Calcium-based systems

- Polyurea

- Aluminum Complex

Each thickener type is designed to perform optimally within specific operating environments and application requirements.

4.3 Additive Package

Additives are incorporated to enhance grease performance and protect components under demanding conditions. Typical additives include:

- Anti-wear additives

- Extreme pressure (EP) additives

- Antioxidants

- Rust and corrosion inhibitors

The additive system largely determines grease performance under high loads, elevated temperatures, moisture exposure, and corrosive environments.

5. Key Physical and Chemical Properties of Lubricating Grease

When selecting lubricating grease, several technical properties should be carefully evaluated:

- NLGI consistency grade, indicating grease hardness or softness

- Dropping point and thermal resistance

- Mechanical stability under shear and vibration

- Water resistance and corrosion protection

- Oxidation stability over time

These parameters help determine whether a grease is suitable for the actual operating conditions of the equipment.

6. The Role of Lubricating Grease in Modern Industry

As modern industry continues to prioritize efficiency, reliability, and reduced maintenance costs, lubricating grease plays a critical role in achieving these objectives.

High-quality lubricating grease helps to:

- Reduce friction and wear between contact surfaces

- Protect components from dust, water, and contaminants

- Minimize vibration and operational noise

- Extend maintenance intervals and equipment service life

For continuously operating systems or components with limited accessibility, the correct grease selection is often a decisive factor in overall system reliability.

7. Conclusion: Choosing the Right Lubricating Grease

Lubricating grease should not be viewed merely as a consumable material, but as a technical solution that directly impacts operational efficiency and production costs.

By understanding the chemical and physical nature, structure, and functional role of lubricating grease, businesses can:

- Select the right grease for each application

- Reduce the risk of equipment failure

- Optimize long-term maintenance strategies

For more in-depth technical insights and OEM grease solutions tailored to real industrial operating conditions, visit oemgrease.com