The Key to Performance: Understanding Lithium Grease Quality

Lithium grease is the most widely used lubricating grease in the world, highly valued for its versatility across both industrial and automotive applications. However, not all lithium greases are created equal. Their performance and service life depend heavily on core characteristics, which are determined by formulation and rigorous testing processes.

Key to Performance: Understanding Lithium Grease Quality.

Lithium grease is the most widely used grease in the world, prized for its versatility in both industrial and automotive applications. However, not all Lithium greases are created equal. The performance and longevity of a grease depends heavily on its core properties, which are determined by its formulation and rigorous testing procedures.

Here is a breakdown of the key characteristics that determine the quality of a Lithium grease:

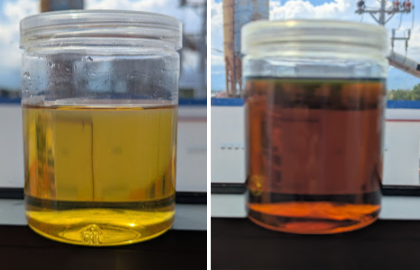

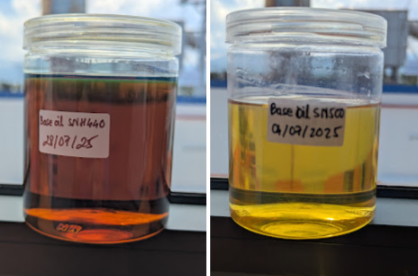

1. Base Oil Quality

• Base oil is the foundation of any grease, making up the largest percentage of its composition. A high-quality grease starts with a high-quality base oil—either mineral or synthetic. The viscosity of this base oil is particularly important because it forms the primary lubricating film, which prevents moving parts from rubbing against each other. A carefully selected base oil will ensure optimum performance across a wide range of temperatures and operating conditions.

2. Dropping Point

• The dropping point is the temperature at which a grease changes from a semi-solid state to a liquid state. This is an important quality indicator, as it indicates the maximum temperature the grease can withstand before it loses its structural integrity and ability to lubricate effectively. A higher dropping point indicates better thermal stability, making the grease suitable for high temperature applications such as wheel bearings and industrial machinery. For example, quality lithium greases typically have dropping points above 180°C.

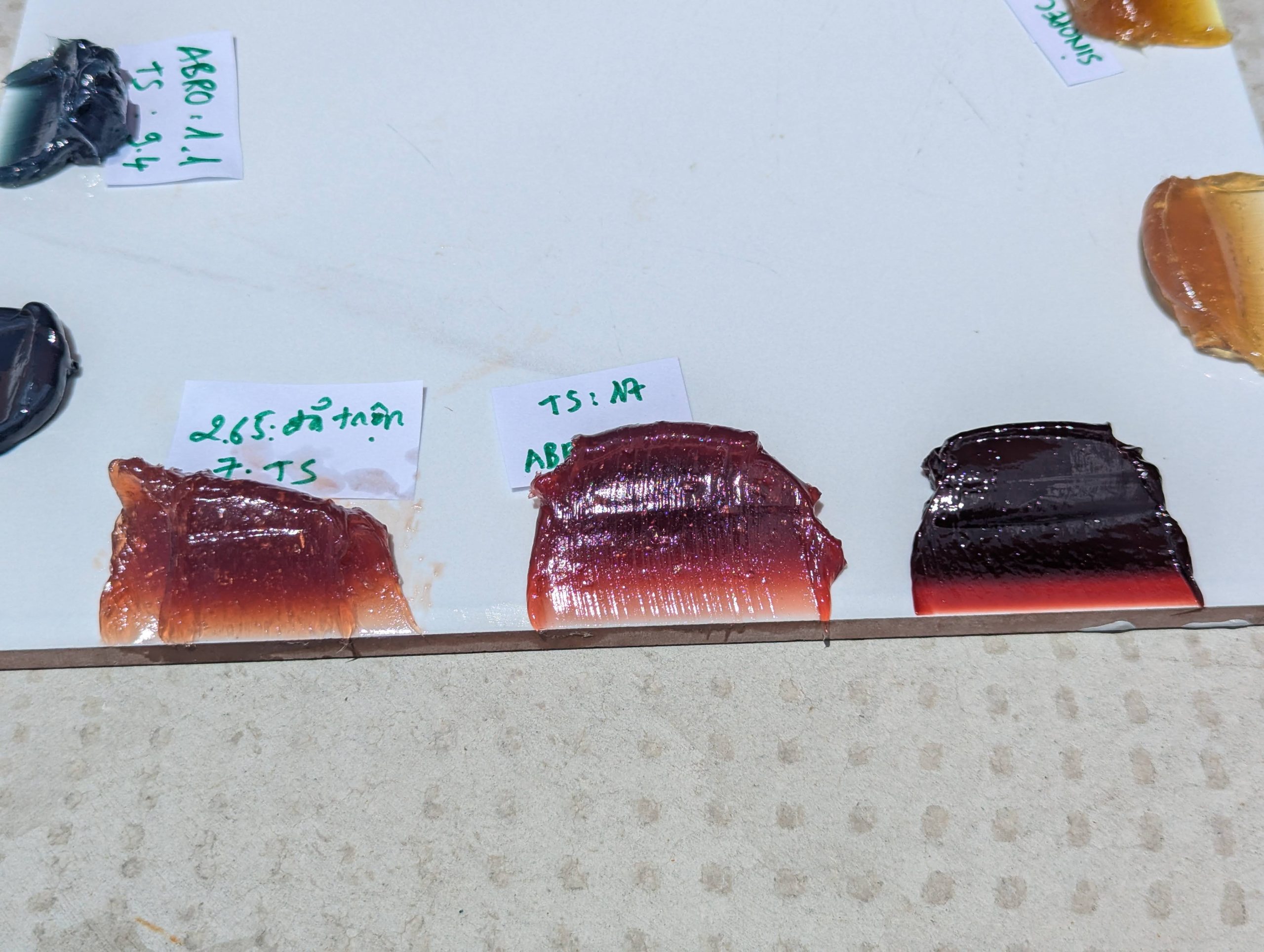

3. Cone Penetration

• Cone penetration is a measure of the thickness or hardness of a grease. It is determined by the depth to which a standardized cone penetrates a sample of grease under specific conditions. This test result corresponds to the NLGI (National Lubricating Grease Institute) classification number. Softer greases (higher cone penetration) are typically used for low-speed, low-load applications, while harder greases (lower cone penetration) are designed for heavy loads and high temperatures. Maintaining the correct cone penetration is important to ensure the grease stays in place and effectively lubricates the contacting parts.

4. Oil Separation

• Greases are essentially a mixture of base oil and thickener (in this case, lithium soap). Oil separation is the natural tendency of the base oil to separate from the thickener over time or under pressure. High-quality lithium greases are formulated to minimize this oil separation, ensuring the lubricant remains stable and effective over time. Excessive oil separation can lead to loss of lubrication and the risk of component failure.

5. Extreme Pressure (EP) Additives

• For applications involving heavy loads, shock loads, or high friction, base oils alone may not be enough to prevent direct metal-to-metal contact. This is where extreme pressure (EP) additives come into play. These specialized chemical compounds react with metal surfaces under extreme pressure to form a protective layer, preventing wear and extending component life. High-quality lithium greases formulated with the right EP additives provide superior protection and reliability in harsh environments.

By carefully considering the key quality parameters—base oil, dropping point, penetration, oil separation, and the presence of EP additives—you can ensure you are selecting a lithium grease that will provide consistent, long-lasting performance and protect your valuable equipment.